The Challenge

The process of manual tracking and barcode scanning at Froedtert Hospital resulted in time inefficiencies, human documentation errors, and limited inventory visibility.

The Solution

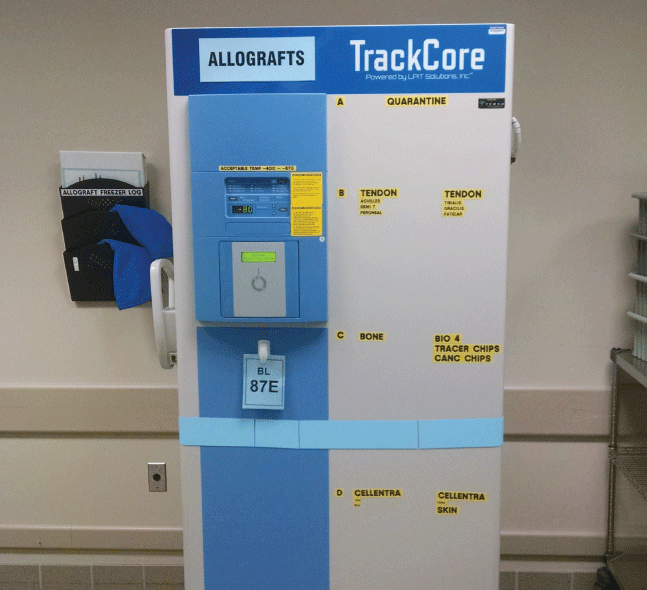

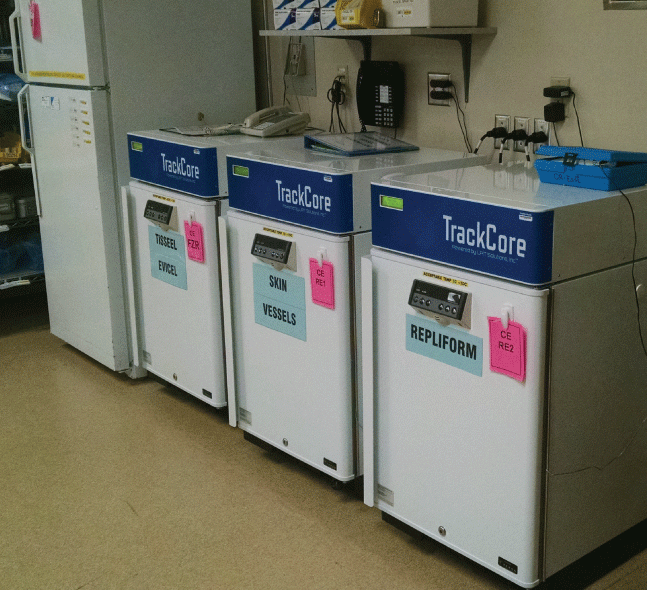

Froedtert Hospital integrated TrackCore, Inc.’s inventory tracking software, TrackCore Operating Room, and Terso Solutions, Inc.’s RAIN RFID enabled enclosures, which eliminated manual tracking errors and resulted in real-time inventory visibility.

About Froedtert Hospital

Froedtert Hospital is the primary teaching affiliate for the Medical College of Wisconsin. A 585-bed academic medical center nationally recognized for exceptional physicians and nurses, research leadership, specialty expertise, as well as state-of-the-art treatments and technology. Froedtert Hospital is a referral center for advanced medical practice care in 37 specialties with over 1,000 students in training. Froedtert Hospital, in partnership with the Medical College of Wisconsin, has more than 2,000 research studies including clinical trials; and is the only level 1 trauma center in the region. As of June 30, 2017, Froedtert Hospital had 29,386 patient admissions, 71,989 emergency visits, 3,440 trauma center patient evaluations, 2,701 births, 97 kidney transplants, 10 heart transplants, and 809,191 outpatient visits.

The Challenge

Froedtert Hospital identified an operational pain point in their surgery departments that many other hospitals also find themselves faced with – the tracking and overall management of tissue and implant inventory. Froedtert Hospital’s challenge was having limited inventory visibility and identifying expired or recalled product stored at the hospital.

Estimates indicate that the operating room represents upwards of 40-60% of a hospital’s total supply expenditures, yet optimizing the OR’s supply management has long been a challenge.

Froedtert Hospital determined their current manual tracking process was unsustainable and research pointed them to an automated inventory management system to improve their processes. To do this, Froedtert Hospital implemented TrackCore Inc.’s tissue and implant tracking software, TrackCore Operating Room, and in 2015 installed RAIN RFID-enabled enclosures from Terso Solutions. The adoption of this technology has seamlessly automated Froedtert Hospital’s tracking process, which has eliminated record keeping from being top-of-mind for nurses and other hospital staff.

The Solution: Real-time Inventory Management Utilizing RFID Technology

Since their initial go-live, Froedtert Hospital has tracked approximately 10,000 high dollar tissues and implants and currently stores approximately 1,800 items at any given time.

In the surgery cores, Froedtert Hospital has a total of nine (9) cold storage RAIN RFID-enabled units, including four ultra-low temperature (ULT) freezers (-86 to -50°C), two compact freezers (-25 to -15 °C ), and three refrigerators (2 to 8 °C). This newly implemented workflow allows a nurse to access the locked RFID enclosure using a personal ID badge, grab the RFID-tagged inventory item(s) needed, shut the door, and return to the surgical suite. Prior to storage, all products are labeled with RFID tags. The RFID enclosures automatically track who took the item, the time it was removed and the temperature of the item when it was removed from storage. This transactional data is sent directly to the TrackCore Operating Room software to automatically track the chain of custody and monitor the integrity of the products. Froedtert Hospital no longer depends on manual processes and data entry with the new automated system. The hospital is now able to track items swiftly and accurately.

Stored inventory at the hospital can be quickly located, and staff who last handled it can be easily identified. Inventory is logged through the TrackCore Operating Room software, making follow up and reconciliation easy and efficient.

Prior to implementing TrackCore Operating Room with RFID technology, Froedtert Hospital had three full time staff members tracking and monitoring biologics and other high-value inventory in the Operating Room. The streamlined process now only requires one staff member. The automated system enables staff to spend more time on the tasks they enjoy – such as further evaluation of drugs and medical products that can help in better addressing illnesses as well as improving patient safety and outcomes.

Compliance Regulation and Operational Processes Made Easy

The TrackCore and Terso integrated solution has greatly changed operational processes around the management of inventory to be more exact and simplified, all while increasing Froedtert Hospital’s ability to meet strict and growing JCAHO and FDA compliance regulations. Since the implementation of this inventory management system, Froedtert Hospital passed the Joint Commission audits with zero instances due to the traceability, real-time visibility, and accuracy of TrackCore Operating Room and RFID-enabled enclosures. For Donna Hafemeister, a Registered Nurse and Implant Coordinator at Froedtert Hospital, the immediate impact of the automated RFID inventory system was pretty clear.

Not only does TrackCore’s system allow nurses to do away with the operational processes and the additional time it takes to log items, its benefits expand to hospital audits. “UNOS (United Network of Organ Sharing) and MTF (Musculoskeletal Transplant Foundation) came into the hospital [for audits] and when they saw TrackCore integrated with RFID enclosures they said ‘This is great, you have RFID!’ It makes the job of auditing much easier. The auditor was familiar with RFID technology, but was most impressed with the ‘trackability’ of the software system,” said Hafemeister.

Conclusion

With the success of this program, Froedtert Hospital has realized the ease of implementation and scalability, and is seeking to expand their automated inventory management system to include RAIN RFID-enabled ambient cabinets for storing tissue and other high-value inventory. Additionally, this program has the potential to expand to other facilities and departments for a fully integrated inventory management system. Froedtert Hospital has identified additional value in both TrackCore and RFID technology to be – accurate record keeping, decreasing inventory carrying counts which has resulted in time, money and valued resource savings.

About TrackCore, Inc.

TrackCore, Inc. is a privately held company headquartered in Grand Rapids, MI. TrackCore began with a vision and commitment to improve patient safety surrounding tissue and implants. TrackCore Operating Room was launched in 2006 and is now the industry leading, flagship product of TrackCore, Inc. designed to eliminate the need for arduous manual processes surrounding tissues and implants. TrackCore Operating Room is now in over 550 hospitals with over 600 RFID implementations, nationwide. TrackCore, Inc. continues to invest in its products and has expanded the product offering to include TrackCore Interventional and TrackCore SameDay. TrackCore Interventional is a product designed to control costs and improve patient care through consumable tracking. TrackCore SameDay automates the bill-only process for consigned special-order implants. Visit www.trackcoreinc.com for more information.

About Terso Solutions

Terso Solutions, Inc. is the leading provider of automated inventory management solutions for tracking high-value medical and scientific products in healthcare and life science. Terso Solutions, Inc. is backed by 14 years of RFID product development and

implementation experience. Terso’s product line includes RAIN RFID cabinets, refrigerators, freezers (-20C to -80C), smart rooms, and mobile solutions. Terso has deployed over 2,100 RAIN RFID-enabled sensors worldwide. Headquartered in Madison, WI, Terso Solutions is a wholly-owned subsidiary of the Promega Corporation. Visit www.tersosolutions.com for more information.